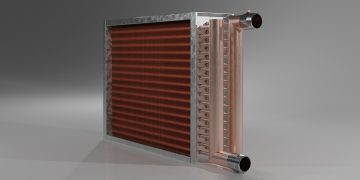

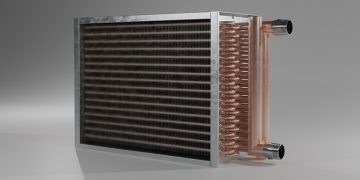

Marlo has extensive experience meeting the rugged demands of process heating and process cooling applications.

The demanding environments require heat transfer coils with more durable features and/or materials than typical commercial HVAC coils.

Our industrial process coils are available in a wide range of special materials and thicknesses designed to meet the unique needs of many different industries. From the tight temperature and humidity tolerances of aerospace and automotive applications to the corrosive environments of chemical and pharmaceutical manufacturing – and everything in between – Marlo’s custom designed process heating and cooling coils get the job done while withstanding any challenging conditions.

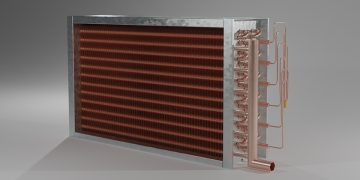

These industrial coils can use chilled water, brine solutions or refrigerants for process cooling, and hot water or steam for process heating. Some of the many ways we build added strength and durability into our process coils include:

- Special tube materials such as stainless steel and copper nickel

- Continuous plate type fins, in aluminum, copper and stainless steel

- Heavy gage galvanized steel casings

- High performance staggered tube pattern

- Tube sheets with extruded holes for longer life

- Corrosion-resistant coatings

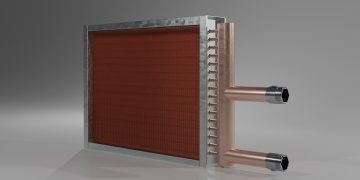

Airtight Coil Housings

Many industrial processes require a coil to be installed in an airtight housing to allow heat transfer while preventing the cross contamination of process air and ambient air. For these situations, Marlo airtight housings are constructed from heavy gauge materials that are selected for suitability based on each specific application. Features of our airtight coils include:

- Designed for pressures from 10” to 10 PSI (higher available)

- Coils can be removable or permanently mounted

- Gaskets for doorplates are selected for temperature and chemical resistance

- Available with integral drain pans for condensing applications

- Transitions and flanges are available to mate housings to square or round ducts

More Products

Related News

Contact

For any further information or to request a quote